Vegware is made from plants using renewable, lower carbon, recycled or reclaimed materials, and designed to be commercially compostable with food waste, where accepted. Compostables are a practical solution for single-use food-contaminated disposables, allowing foodservice to achieve their sustainability goals.

Vegware uses a variety of renewable plant-based materials to manufacture our product range.

In its finished form, Vegware packaging is compostable in commercial facilities, where accepted.

Waste hierarchy of 3 R's is the order of priority of actions to be taken to reduce the amount of waste generated, and to improve overall waste management processes and programs. Bellroy puts its heart, soul and countless design hours into helping the world carry with simplicity and ease. Every piece has been deeply considered, for the best of life's little moments.

Paper & card

Sustainably sourced paper and cardboard, using recycled content where we can. Uses include Vegware hot cups, soup containers, paper straws, Bon Appetit bowls, and various takeaway containers.

Inks

We use vegetable and water-based inks that have a great print finish. Our in-house designers can create custom print for a wide range of our products.

Polylactic Acid (PLA)

Compostable bioplastic derived from plant sugars. Glucose is extracted from milled corn. It is then fermented to produce lactic acid, which is processed into a polymer and made into pellets. PLA is used in our clear products like cold cups and deli containers, and to line our board-based products. CPLA is crystallised PLA, used when more heat resistance is needed, like with our lids and cutlery.

Bagasse

Made from a by-product of the sugarcane industry.

Bagasse is a stylish eco alternative to polystyrene suitable for hot and cold food. Made from reclaimed sugarcane, our bagasse uses the dry fibrous residue left once sugarcane has been pressed for juice. A high-heat, high-pressure process is applied to press and shape the fibres. Used to make our takeaway boxes, plates and bowls.

Palm leaf

Made from naturally fallen Areca palm leaves in Southern India. Tableware suitable for hot and cold food. Fallen leaves are gathered and cleansed with high pressure water jets. Once dried, they are shaped under heated moulds. There are no coatings, additives or chemicals, just the natural leaf. Used to make our Palm leaf tableware, including plates, platters and bowls.

A clear film made from wood pulp. The wood is sourced from sustainably managed forestry. Cellulose fibres in wood pulp goes through a casting process and regenerates into a certified industrial and home compostable film called NatureFlex. Used for our clear bags and some of our products’ clear windows, it is greaseproof and suitable for hot and cold food.

Vegware holds the deepest set of compostability certification in the sector. Our full product range can be commercially composted with food waste where accepted. Independent bodies have certified our products can break down in under 12 weeks in industrial composting facilities. The most widely used compostability standards are the European EN13432 and the American ASTM D6400. They are largely equivalent, and include the following elements:

Biodegradation – materials turn to soil through microbial action at the same rate as cellulose (paper)

Disintegration – the materials fall into small pieces

Eco-toxicity– seeds can germinate in the resulting compost – i.e. it is useful for plant growth

Heavy metals– the compost is safe to go onto land

Learn how compostables are the key to recycling everything

Let us answer your questions about Vegware products

Contact us

For product inquiries, contact

3d Plants Made From Recycled Materials Images

- What is Vegware made from?

- Vegware is made from plants using renewable, lower carbon, recycled or reclaimed materials. We use a variety of plant-based materials – visit Our materials page for more information.

- Is Vegware food safe?

- Vegware is certified food safe. We hold the market's most comprehensive food migration certification.

- Is Vegware oven safe? Can I microwave or freeze it?

- We encourage customers to request product samples, as each kitchen is different, so samples allow you to test Vegware with your menu offerings and see how they work in your ovens, microwaves, refrigerators and freezers. Products that are Vegware-approved for a commercial kitchen appliance, such as hot cabinets, are referenced in the product's description.

- Are Vegware products vegan?

- Our products are made from plants using renewable, lower carbon, recycled or reclaimed materials. We use synthetic glues to bind our materials and have confirmation that they do not contain animal by-products.

- Isn’t using corn for bioplastics taking up land that could be used to feed people?

- If half of the world’s plastic production switched to crop-based bioplastics, the industry would still only require 3% of the world’s cultivated land. Bioplastics are typically made from materials that are not suitable for human consumption. For example, producers do not use food grade corn in the manufacture, thus it can be grown on outlying agricultural land and not interfere with food production.

- How should I store Vegware products?

- Do not store Vegware near heat – for example not in direct sunlight or near an oven or radiator. Vegware is best stored at temperatures not more than 40°C.

- Are Vegware products made in the UK?

- Vegware is a global brand, operating across a range of markets. As such, our supply chain is spread across a range of territories including the UK and Asia. We manufacture our products close to the source of our raw plant-based materials, so that when transported, Vegware products are in their finished form.

- What's the shelf life for Vegware products?

- Generally speaking, Vegware products have a shelf life of up to one year.

Materials ranging from precious metals to broken glass, from old newspapers to plastic spoons, can be recycled. The recycling process reclaims the original material and uses it in new products.

3d Plants Made From Recycled Materials For Sale

Recycling can be done internally (within a company) or externally (after a product is sold and used). Since the recovered material never left the manufacturing plant, the final product is said to contain preconsumer waste. External recycling occurs when materials used by the customer are returned for processing into new products. Materials ready to be recycled in this manner, such as empty beverage containers, are called postconsumer waste.

Download game mega man 11 pc. Just about any material can be recycled. On an industrial scale, the most commonly recycled materials are those that are used in large quantities.

3d Plants Made From Recycled Materials

Steel. There are two methods of making steel using recycled material: the basic oxygen furnace (BOF) method and the electric arc furnace (EAF) method. The BOF method involves mixing molten scrap steel in a furnace with new steel. Steel made by the BOF method typically is used to make sheet-steel products like cans, automobiles, and appliances. The EAF means that scrap steel is placed in a furnace and melted by electricity that arcs between two carbon electrodes. Limestone and other materials are added to the molten steel to remove impurities. Steel produced by the EAF method usually is formed into beams, reinforcing bars, and thick plate.

Aluminum. Recycling aluminum provides a stable, domestic aluminum supply. Aluminum cans almost always produce a profit in community recycling programs. Cans brought to collection centers are crushed, baled, and shipped to regional mills or reclamation plants. The cans are then shredded to reduce volume and heated to remove coatings and moisture. Next, they are put into a furnace, melted, and formed into ingots, or bars. The ingots go to another mill to be rolled into sheets. The sheets are sent to a container plant and cut into disks from which new cans are formed.

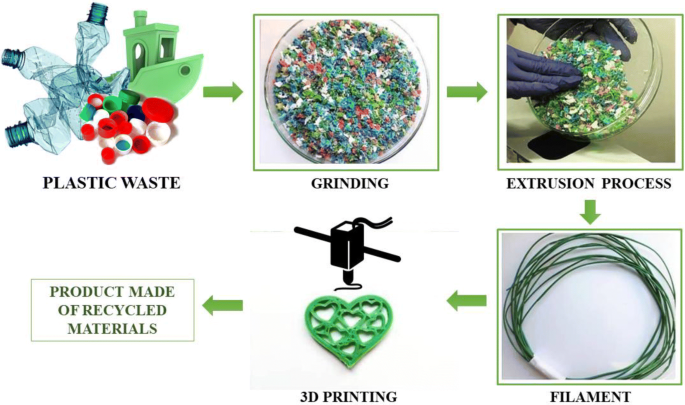

Plastics. Plastics are more difficult to recycle than metal, paper, or glass. One problem is that any of seven categories of plastics can be used for containers alone. For effective recycling, the different types cannot be mixed. The recycling process for plastic normally involves cleaning it, shredding it into flakes, then melting the flakes into pellets. The pellets are melted into a final product.

Paper and Paper Products. Paper products that include cardboard containers, wrapping paper, office paper and newsprintcan be recycled.

In newspaper recycling, old newspapers are collected and searched for contaminants such as plastic bags and aluminum foil. The paper goes to a processing plant where it is mixed with hot water and turned into pulp in a machine that works much like a big kitchen blender. The pulp then goes to a large vat where the ink separates from the paper fibers and floats to the surface. The ink is skimmed off, dried and reused as ink or burned as boiler fuel. The cleaned pulp is mixed with new wood fibers to be made into paper again.

Glass. Scrap glass taken from the glass manufacturing process, called cullet, has been internally recycled for years. The scrap glass is economical to use as a raw material because it melts at lower temperatures than other raw materials, thus saving fuel and operating costs.

Glass that is to be recycled must be relatively free from impurities and sorted by color. Glass containers are the most commonly recycled form of glass, and their colors are flint (clear), amber (brown), and green. The recycled glass is melted in a furnace and formed into new products.

Chemicals and Hazardous Waste. Household hazardous wastes include drain cleaners, oven cleaners, window cleaners, disinfectants, motor oil, paints, paint thinners, and pesticides. Most municipalities ban hazardous waste from the regular trash. Periodically, citizens are alerted that they can take their hazardous waste to a collection point where trained workers sort it, recycle what they can, and package the remainder in special leak-proof containers called lab packs, for safe disposal. Typical materials recycled from the collection drives are motor oil, paint, antifreeze, and tires. Business and industry have made much progress in reducing both the hazardous waste they generate and its toxicity.

3d Plants Made From Recycled Materials Pictures

Nuclear Waste. Certain types of nuclear waste can be recycled, while other types are considered too dangerous to recycle. Low-level wastes include radioactive material from research activities, medical wastes, and contaminated machinery from nuclear reactors. Nickel is the major metal of construction in the nuclear power field and much of it is recycled after surface contamination has been removed.

High-level wastes come from the reprocessing of spent fuel and from the processing of nuclear weapons. These wastes emit gamma radiation, which can cause birth defects, disease, and death. High-level nuclear waste is so toxic it is not normally recycled. Instead, it is fused into inert glass tubes encased in stainless steel cylinders, which are then stored underground.